Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Ceramics

to Carbon materials

Graphite molds for continuous casting

Applications of graphite in continuous casting

Graphite is widely used as a material for Continuous casting molds.

Continuous casting is a casting method in which the steps of pouring, solidification and withdrawal (extraction) of the casting from an open end mold are carried out continuously.

Graphite molds (dies) may be used in both types of the process: vertical continuous casting and horizontal continuous casting.

Most molds are fabricated from isostatically pressed graphite, however extruded graphite is also used for vertical casting of large ingots.

The following alloys are manufactured by continuous casting in graphite molds:

- Silver and silver alloys (Ag)

- Coinage alloys (Cu-Ni)

Characteristics of graphite for continuous casting molds

- Low wettability

In order to prevent sticking and breaking a casting extracted from the mold its material should possess poor adhesion to the solidifying metal. It is achieved by low wetting of the mold by the liquid metal. Graphite is not wettable by most molten non-ferrous metals and alloys. Ferrous alloys (eg. Cast irons) wet graphite due to the reaction with carbon, which results in formation of carbides Fe3C. Graphite is also wetted by alloys containing nickel (more than 6% of nickel), zinc or tin.

- High thermal conductivity

Heat liberated during cooling down and solidification of the cast metal should be removed from the mold. The value of the heat transferred through the mold in a time unit determines the solidification rate and the pulling (extraction) speed of the casting. Thermal conductivity of the mold material should be high enough to provide fast heat removal. Thermal conductivity of graphite used for continuous casting molds is in the range 560-960 BTU*in/hr*ft²*ºF (80-140 W/m*K), which is comparable to thermal conductivity of metals: aluminum 1540 BTU*in/hr*ft²*ºF (222 W/m*K); steel 450 BTU*in/hr*ft²*ºF (65 W/m*K). Thermal conductivity of graphite depend on temperature: it decreases to a half as the temperature rises to 1300°F (704°C).

Casting mold is heated inside by the entering molten metal and cooled down from the outside by the water-cooled copper jacket (or directly by water). The resulting temperature distribution throughout the mold is extremely non-uniform. Low thermal expansion of the mold material helps to prevent distortion the mold shape and secures the casting geometry. Thermal expansion of graphite is 2-2.8*10-6 °F-1 (3.5-5*10-6 °C-1), which is considerably lower than that of metals: aluminum 13*10-6 °F-1 (23*10-6 °C-1); steel 7*10-6 °F-1 (13*10-6 °C-1).

Thermal shock resistance of a material may be estimated in accordance to the formula:

Rs = (λ*σF)/(α*E)

Where: Rs– thermal shock resistance; λ- thermal conductivity; σF– flexural strength; α- coefficient of thermal expansion (CTE); E– modulus of elasticity.

Graphite has excellent thermal shock resistance due to favorable combination of high thermal conductivity, low coefficient of thermal expansion, low modulus of elasticity (1500 ksi / 10.3 GPa) and relatively high flexural strength (7500 psi / 52 MPa).

- Self-lubrication

Graphite is a solid lubricant. Low friction between the mold surface and the solidifying metal ensures smooth withdrawl (extraction) of the casting without cracks and minimizes thickness of the defective periferial skin. Specific layered crystal structure of graphite determines its self-lubricating properties providing low friction without additional oil lubrication.

- Good mechanical strength

In contrast to other materials mechanical strength (tensile strength, compressive strength, flexural strength) of graphite increases with a temperature rise.

- Good machinability

Graphite is easily machined. Molds of complicated shapes with close tolerances may be obtained by milling, turning, sawing, grinding and surface finishing. Fine finish of the inner mold surface (ground or polished) is important for decrease of the material wettability and friction. Good quality of the outer surface ensures minimal air gap between the mold and the water-cooled jacket, which results in better heat transfer.

to top

Design of graphite molds for continuous casting

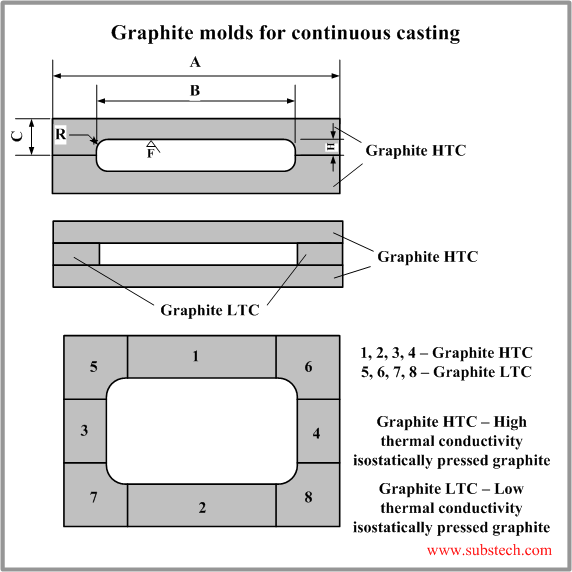

Examples of possible mold designs are presented on the figure.

In order to diminish the difference in cooling rates between the casting regions close to the mold corners (and side walls) and the central regions, which are cooled down slower, mold may be made of two different graphite grades. Corner and side parts are made of a graphite grade with low thermal conductivity.

Wall thickness of rectangular graphite molds is usually 0.4”-1” (10-25 mm). Wall thickness of round molds is 0.2”-0.5” (5-13 mm). Castings of larger cross-section are cast in molds with thicker walls.

to top

Graphite molds lifetime

Depending on the work conditions and the alloy type graphite mold may operate continuously for 8-120 hrs.

After each casting run the mold may be repaired by machining the work surfaces.

Following factors determine the graphite mold lifetime:

- The cast alloy composition. Alloys containing elements wetting graphite (Fe, Ni, Zn, Sn) shorten the mold life.

- Liquidus-solidus interval of the cast alloy. Large liquidus-solidus temperature interval increases the contact time between the mold and solidifying metal enhancing wetting.

- The graphite density and porosity. In order to achieve a longer service life of the molds and to improve the casting surface quality dense low porosity graphite grades are used for casting cast irons and alloys containing nickel, zinc and tin.

- Casting temperature. Higher casting temperatures enhance wetting resulting in shorter mold life.

- Cooling rate. Fast cooling decreases the contact time between the mold and solidifying metal enhancing wetting.

- Absorption of liquids (humidity) and gases by the mold material prior to casting. Liquids and gases absorbed by graphite may cause high pressure in the mold when the molten metal enters it. The pressure may broke the mold. It is recommended to dry mold before casting at 250-350°F (120-177ºC) for 24-12 hrs.

Properties of some graphite grades for continuous casting

Related internal links