Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Aluminum alloys

Aluminum extrusion

Extrusion

Extrusion is a metal forming process involving shaping a metal billet (hot or cold) by forcing it through a die with an opening.

Extrusion does not produce tensile stresses (only compression and shear) in the deformed metal bar therefore it does not tear.

The two possible schemes of extrusion are presented in the picture:

The metal billet is placed to the container of the extrusion press. The die with an opening is mounted at the end of the container.

When the hydraulically driven ram presses the billet, the metal starts to flow through the opening forming the extruded product of the required cross section.

In the direct extrusion the extruded metal flows in the direction of the ram motion.

In the indirect extrusion the metal flows in the direction opposite to the ram motion.

Indirect extrusion requires a lower force than direct process as there is no friction between the billet and the inside walls of the container.

to top

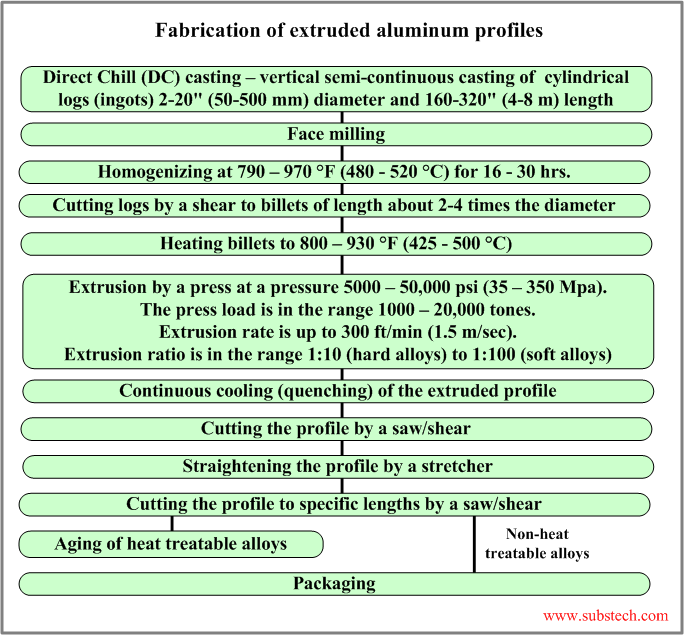

Aluminum extrusion process

Cylindrical billets of extrusion aluminum alloys are fabricated by the Direct Chill (DC) casting method. Aluminum extrusion process is based on a flow of hot and compressed aluminum alloy through the steel die. The aluminum billet is compressed in the heated container of the extrusion press by a hydraulically driven ram.

The diagram below presents the main steps of the aluminum extrusion process:

to top

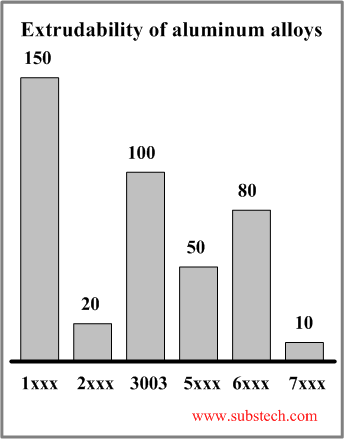

Extrudability of aluminum alloys

Extrudability of an alloy is the maximum relative extrusion speed, which allows to obtain extruded profile without tearing and cracks.

Extrudability of an alloy is the maximum relative extrusion speed, which allows to obtain extruded profile without tearing and cracks.

Extrudability of an alloy depends on the following factors:

- Alloy composition

- Billet temperature

- Extrusion ratio

- Profile shape

- Casting micro-structure

- Level of Microsegregation determined by the homogenizing annealing parameters

The Aluminum alloys having good extrudability are:

- Wrought aluminum-magnesium alloys (5xxx) containing up to 2.5% of manganese (eg. 5052)

- Most of the Wrought aluminum-magnesium-silicon alloys (6xxx) (except 6066)

The alloys having moderate extrudability are:

- Wrought aluminum-magnesium alloys (5xxx) containing 2.5-4% of manganese

The alloys having poor extrudability are:

- Wrought aluminum-magnesium alloys (5xxx) containing more than 4% of manganese

Properties of extruded aluminum alloys

| Designation | Forming | Machining | Welding | Brazing | Protective anodizing | Aesthetic anodizing | Temper | Tensile strength, ksi/MPa | Yield strength, ksi/MPa | Elongation, % |

|---|---|---|---|---|---|---|---|---|---|---|

| 1060 | good | poor | good | good | excellent | excellent | O | 1.233 / 8.5 | 0.363 / 2.5 | 25 |

| 1100 | good | poor | good | good | good | good | O | 1595 / 11 | 435 / 3.0 | 25 |

| 2014 | good | good | not suitable | not suitable | fair | not suitable | T4 | 50 / 345 | 35 / 241 | 12 |

| 2014 | good | good | not suitable | not suitable | fair | not suitable | T6 | 60 / 414 | 53 / 365 | 7 |

| 2024 | good | good | not suitable | not suitable | fair | not suitable | T3 | 57 / 393 | 42 / 290 | 12 |

| 2024 | good | good | not suitable | not suitable | fair | not suitable | T81 | 64 / 441 | 56 / 386 | 4 |

| 3003 | excellent | fair | good | good | good | poor | O | 14 / 97 | 5 / 34 | 25 |

| 5083 | good | good | good | not suitable | good | good | O | 39 / 269 | 16 / 110 | 14 |

| 6061 | good | good | good | good | good | fair | T4 | 26 / 179 | 16 / 110 | 16 |

| 6061 | good | good | good | good | good | fair | T6 | 38 / 262 | 35 / 241 | 8 |

| 6063 | good | good | good | good | good | good | T1 | 17 / 117 | 9 / 62 | 12 |

| 6063 | good | good | good | good | good | good | T4 | 19 / 131 | 10 / 69 | 14 |

| 6063 | good | good | good | good | good | good | T5 | 22 / 152 | 16 / 110 | 8 |

| 6063 | good | good | good | good | good | good | T6 | 30 / 207 | 25 / 172 | 8 |

| 6101 | good | good | good | good | good | good | T6 | 29 / 200 | 25 / 172 | 15 |

| 6463 | good | good | good | good | good | excellent | T1 | 17 / 117 | 9 / 62 | 12 |

| 6463 | good | good | good | good | good | excellent | T5 | 22 / 152 | 16 / 110 | 8 |

| 6463 | good | good | good | good | good | excellent | T6 | 30 / 207 | 25 / 172 | 8 |

| 7075 | fair | good | not suitable | not suitable | fair | poor | T6 | 78 / 538 | 70 / 483 | 7 |

Applications of extruded aluminum

About half of the aluminum products are fabricated by extrusion:

- Sheathing tubes for wire and cable industry (1060)

- Chemical equipment, pressure vessels, condensers, furniture (3003)

- High strength bus conductors (6101)

Related internal links

to Metals

to Aluminum alloys