Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Metal joining technologies (welding, brazing, soldering)

Resistance Welding (RW)

Dr. Dmitri Kopeliovich

Resistance Welding is a welding process, in which work pieces are welded due to a combination of a pressure applied to them and a localized heat generated by a high electric current flowing through the contact area of the weld.

Heat produced by the current is sufficient for local melting of the work piece at the contact point and formation of small weld pool (”nugget”). The molten metal is then solidifies under a pressure and joins the pieces. Time of the process and values of the pressure and flowing current, required for formation of reliable joint, are determined by dimensions of the electrodes and the work piece metal type.

AC electric current (up to 100 000 A) is supplied through copper electrodes connected to the secondary coil of a welding transformer.

The following metals may be welded by Resistance Welding:

- Low carbon steels - the widest application of Resistance Welding

Advantages of Resistance Welding:

- High welding rates;

- Low fumes;

- Cost effectiveness;

- Easy automation;

- No filler materials are required;

- Low distortions.

Disadvantages of Resistance Welding:

- High equipment cost;

- Low strength of discontinuous welds;

- Thickness of welded sheets is limited - up to 1/4” (6 mm);

Resistance Welding (RW) is used for joining vehicle body parts, fuel tanks, domestic radiators, pipes of gas oil and water pipelines, wire ends, turbine blades, railway tracks.

The most popular methods of Resistance Welding are:

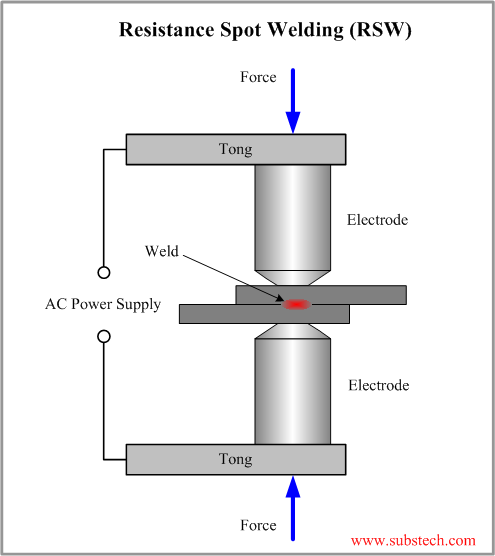

Spot Welding (RSW)

Spot Welding is a Resistance Welding (RW) process, in which two or more overlapped metal sheets are joined by spot welds.

The method uses pointed copper electrodes providing passage of electric current. The electrodes also transmitt pressure required for formation of strong weld.

Diameter of the weld spot is in the range 1/8” - 1/2” (3 - 12 mm).

Spot welding is widely used in automotive industry for joining vehicle body parts.

to top

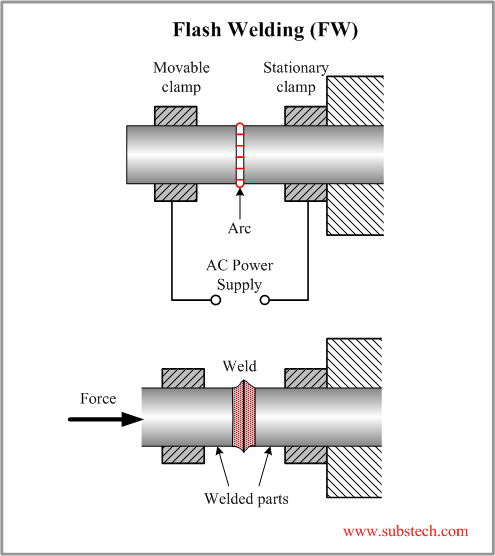

Flash Welding (FW)

Flash Welding is a Resistance Welding (RW) process, in which ends of rods (tubes, sheets) are heated and fused by an arc struck between them and then forged (brought into a contact under a pressure) producing a weld.

The welded parts are held in electrode clamps, one of which is stationary and the second is movable.

Flash Welding method permitts fast (about 1 min.) joining of large and complex parts.

Welded part are often annealed for improvement of Toughnesstoughness of the weld.

Steels, Aluminum alloys, Copper alloys, Magnesium alloys, Copper alloys and Nickel alloys may be welded by Flash Welding.

Thick pipes, ends of band saws, frames, aircraft landing gears are produced by Flash Welding.

to top

Resistance Butt Welding (UW)

Resistance Butt Welding is a Resistance Welding (RW) process, in which ends of wires or rods are held under a pressure and heated by an electric current passing through the contact area and producing a weld.

The process is similar to Flash Welding, however in Butt Welding pressure and electric current are applied simultaneously in contrast to Flash Welding where electric current is followed by forging pressure application.

Butt welding is used for welding small parts. The process is highly productive and clean. In contrast to Flash Welding, Butt Welding provides joining with no loss of the welded materials.

to top

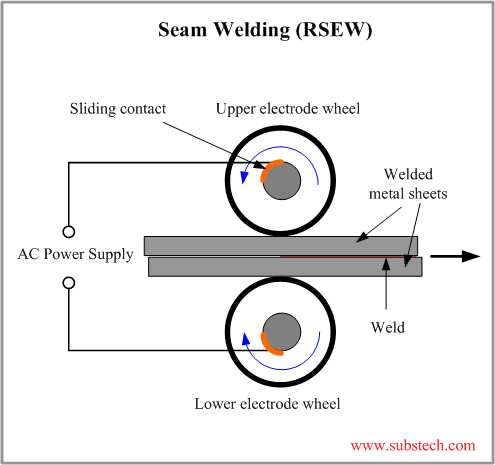

Seam Welding (RSEW)

Seam Welding is a Resistance Welding (RW) process of continuous joining of overlapping sheets by passing them between two rotating electrode wheels. Heat generated by the electric current flowing through the contact area and pressure provided by the wheels are sufficient to produce a leak-tight weld.

Seam Welding is high speed and clean process, which is used when continuous tight weld is required (fuel tanks, drums, domestic radiators).

to top

Related internal links