SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Oil Clearance and Engine Bearings

Hydrodynamic Lubrication

Among all geometric parameters of an engine bearing, oil clearance is the most important. It determines one of the key functions of the bearings – support the creation of hydrodynamic lubrication. In a hydrodynamic bearing, a rotating journal produces a hydrodynamic force that squeezes lubricant through the gap between the journal and bearing surfaces [1]. The hydrodynamic force counteracts the external force of the crankshaft. This prevents direct contact between the bearing and journal surfaces, which are separated by an oil film.

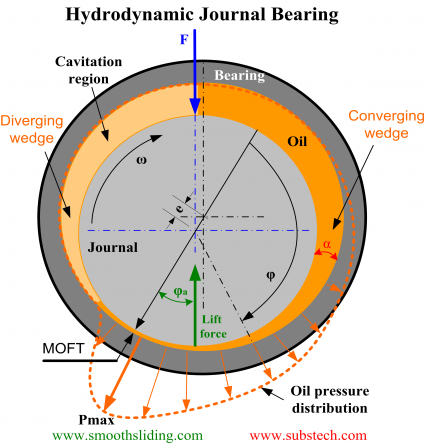

In a hydrodynamic bearing, the loaded rotating journal is always displaced from the concentric position. As a result, a converging gap (wedge) is formed between the bearing and journal surfaces (Fig.1). The wedge parameters are determined by the difference between the diameters. This difference is called oil clearance (or bearing clearance). The presence of an oil wedge is indispensable to the normal operation of a hydrodynamic bearing [2].

Fig. 1 Journal bearing

The rotating journal generates hydrodynamic force. The greater the force, the more the journal center shifts away from the bearing center.

to top

Effect of Oil Clearance on the Parameters of Bearing Lubrication

The hydrodynamic conditions of bearing operation can be calculated theoretically. Software developed by King Engine Bearings (called ENSIM™), is used for simulation of engine bearing performance under various conditions. ENSIM™ is capable of calculating the thermodynamic, dynamic, hydrodynamic and mechanical parameters of bearing operation. When a bearing for a new or existing engine is being designed, theoretical simulation of hydrodynamic lubrication is performed to optimize bearing operation. For the purposes of this article, effects of oil clearance on the parameters of hydrodynamic friction were determined by means of calculations made for high performance bearings working under the following conditions:

- Bearing diameter: 2”

- Bearing length: 1”

- Oil type: 5W50 synthetic

- Oil inlet temperature: 175 °F

- Bearing loads: 5,100 psi and 12,000 psi

- Rotation speeds: 2000 RPM, 4500 RPM and 8000 RPM

The main objective of the calculations was to determine the optimal values of clearance for various operational conditions.

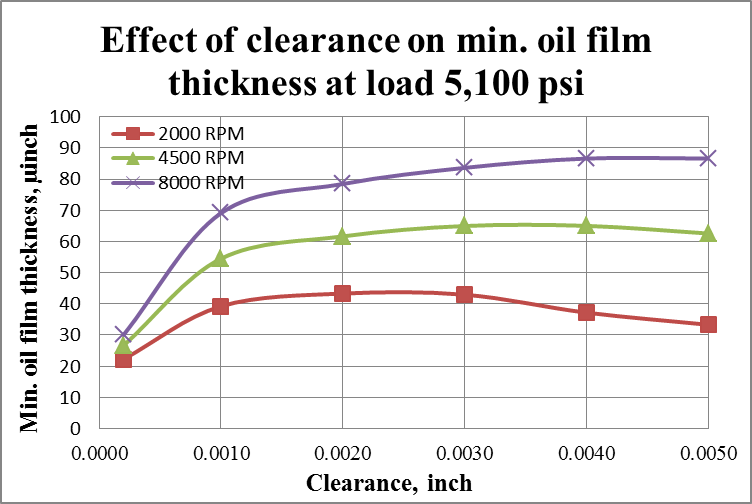

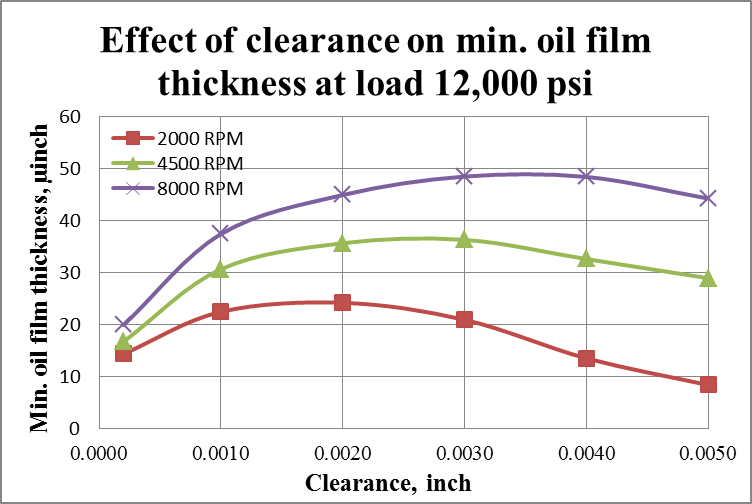

The most important hydrodynamic parameter affected by oil clearance is the value of minimum oil film thickness. It should be as great as possible in order to prevent metal-to-metal contact between the crankshaft journal and the bearings. The results of the calculations of the effect of clearance on min. oil film thickness are presented in Fig.2 and 3.

Fig.2 Effect of oil clearance on min. oil film thickness at load 5,100 psi

Fig.3 Effect of oil clearance on min. oil film thickness at load 12,000 psi

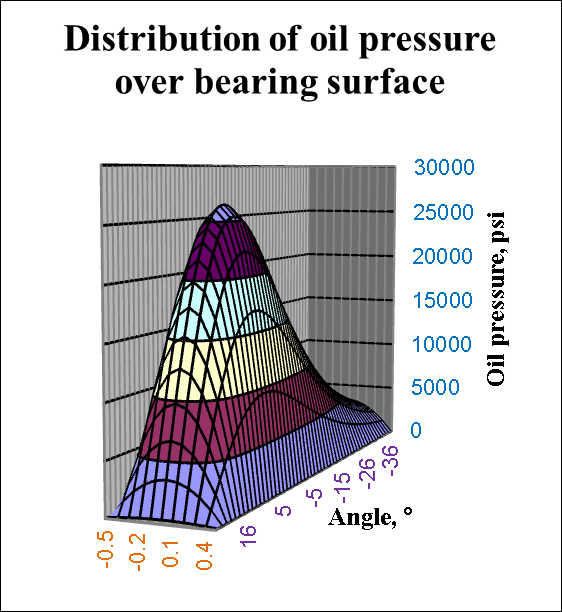

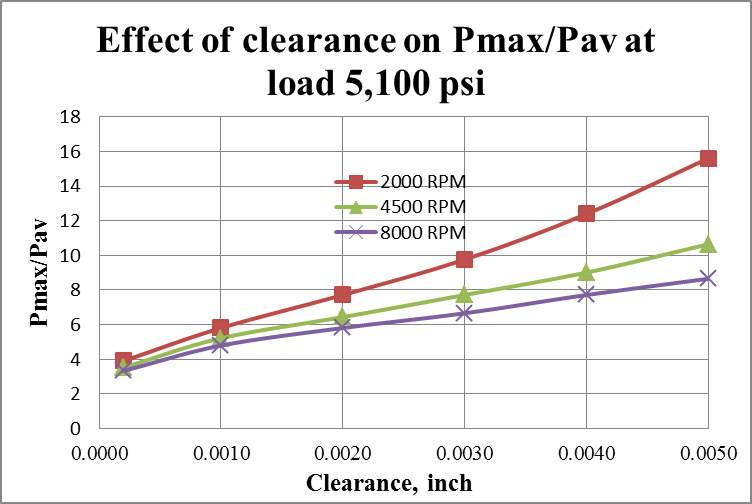

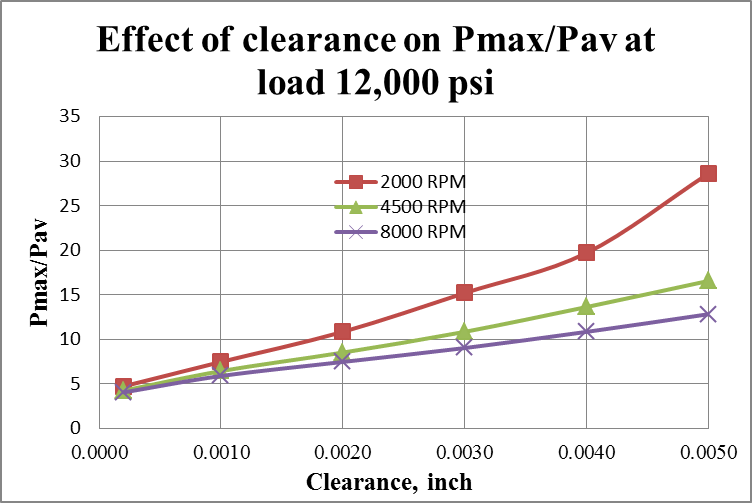

The calculations prove that optimal oil clearance (clearance providing the greatest value of min. oil film thickness) depends on the rotation speed and load applied to the bearing. An increase of oil clearance provides two opposite effects on the value of oil film thickness. On the one hand, oil film thickness increases due to the formation of a larger supporting oil wedge. On the other hand, non-uniformity (localization) of oil pressure, caused by excessive clearance, results in a decrease of oil film thickness. Oil pressure distribution has a peak close to the location of minimum oil film thickness. The value of the peak is dependent on the average load applied to the bearing, the journal rotation speed, lubricant viscosity and the value of journal eccentricity “e” (Fig.1) relative to the bearing. The non-homogeneity of oil pressure distribution is characterized by the ratio Pmax/Pav.

Where: Pav – the average load applied to the bearing surface (5,100 psi or 12,000 psi in our calculations)

Pmax – the peak value of oil pressure

An example of oil pressure distribution is shown in Fig.4.

Fig.4 Distribution of oil pressure over bearing surface

Excessive clearance can produce a decrease in min. oil film thickness, resulting in undesirable metal-to-metal contact. It may also cause fatigue of the bearing material in the area of peak pressure. This phenomenon is known as knocking. The effect of clearance on oil pressure distribution is presented in Fig.5 and 6.

Fig.5 Effect of oil clearance on distribution of oil pressure at load 5,100 psi

Fig.6 Effect of oil clearance on distribution of oil pressure at load 12,000 psi

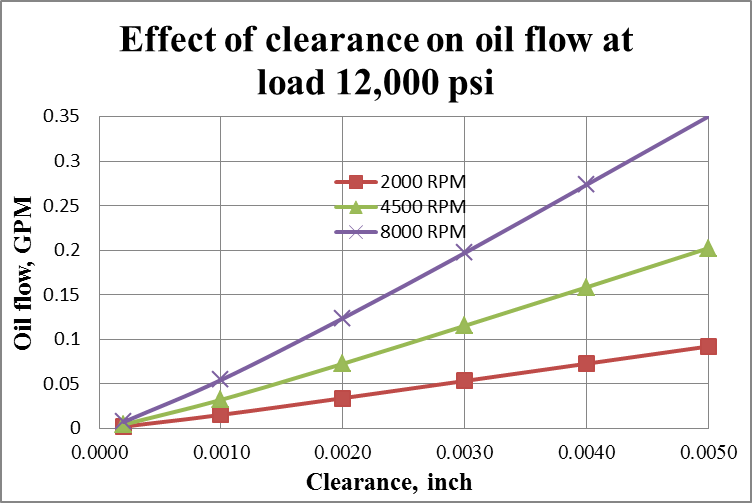

These graphs depict that clearance exceeding 0.003” (in our 2” bearing diameter study) results in substantial non-homogeneity of oil pressure distribution. One of the most wide spread causes of engine bearing failure is oil starvation. Insufficient oil supply may be caused by problems with the oil pump, clogging of oil passages or by excessive leakage of oil out of the bearing due to excessive clearance. Oil leakage has an important positive role – it removes the heat absorbed by the bearing, thus preventing overheating of the oil. However, too large a flow of oil leakage may cause a drop of oil pressure and even oil starvation, which terminates hydrodynamic lubrication. Besides oil clearance, oil viscosity affects the oil leakage rate. Oils having greater viscosity better support oil pressure and reduce oil leakage from the bearings. The influence of clearance on oil flow is seen in Fig.7.

Fig.7 Effect of oil clearance on oil flow

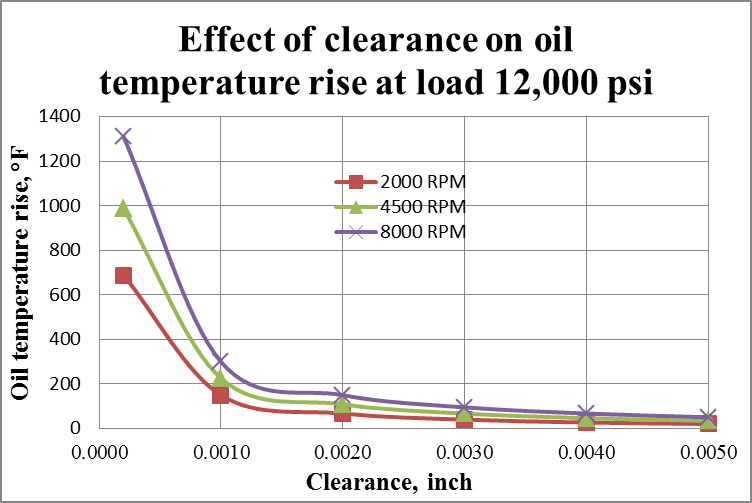

This graph shows that low oil clearance provides low oil leakage and more uniform distribution of oil pressure. However, oil clearance should not be too low due to the following adverse effects: - Tight clearances generate lower hydrodynamic force, which causes a decrease of min. oil film thickness (see Fig.2 and 3). - Bearing housings and crankshaft may distort/deflect at high loads and high rotation speeds. These distortions are much more dangerous in bearings with small clearances. - Excessive heating of the oil caused by friction energy generated at the bearing by high journal rotation speeds. The effect of clearance on oil temperature rise (delta T) is depicted in Fig.8.

Fig.8 Effect of oil clearance on oil temperature rise

to top

Effect of Oil Viscosity

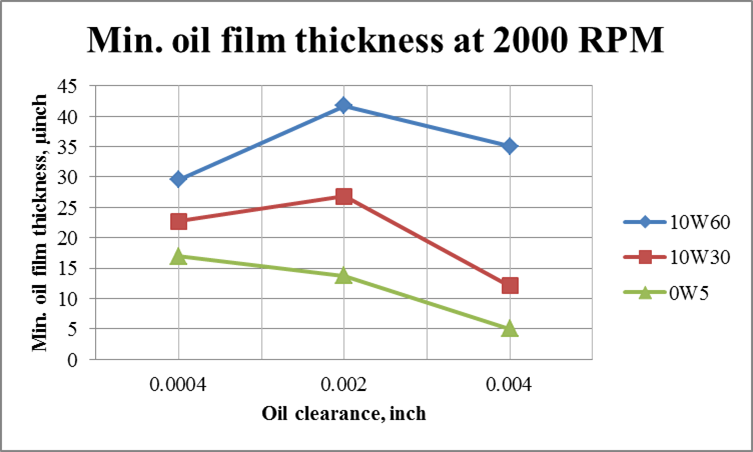

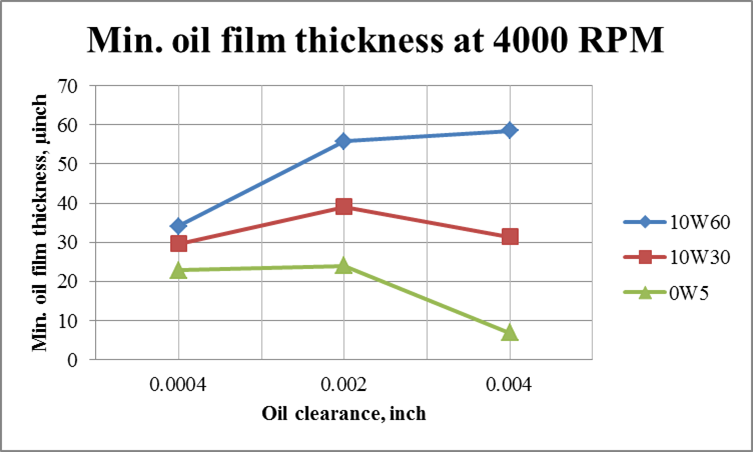

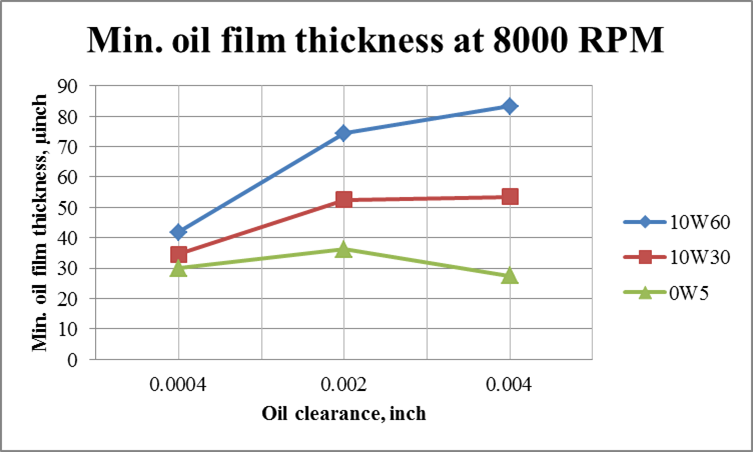

The effect of oil clearance on minimum oil film thickness for oils with different viscosity and at various rotation speeds is demonstrated in Fig.9.

Fig.9 Effect of oil viscosity on minimum oil film thickness at 2000, 4000 and 8000 RPM

The positive effect of oil viscosity on min. oil film thickness for any rotation speed and any oil clearance is evident from the graphs. However, the effect becomes more considerable at greater clearance. The calculations prove that the most viscose oil, 10W60, provides the most stable hydrodynamic regime of lubrication (the greatest value of minimum oil film thickness) with an oil clearance of 0.004” (1/500 of the bearing diameter). Only at the rotation speed of 2000 RPM does minimum oil film thickness slightly decrease (from 41.6 to 35.0 µinch) when the clearance is increased from 0.002 to 0.004”.

The behavior of the most fluid oil (0W5) is quite different. At relatively large clearances its viscosity is too low to create hydrodynamic force sufficient to maintain the required level of min. oil film thickness. This effect is most prominent at low rotation speed 2,000 RPM. The greatest value of oil film thickness is achieved at the lowest clearance of 0.0004” (1/5000 of the bearing diameter). The oil grade with a moderate viscosity index, 10W30, demonstrated the most stable hydrodynamic regime at the clearance value of 0.002”, which equals 1/1000 of the bearing diameter.

to top

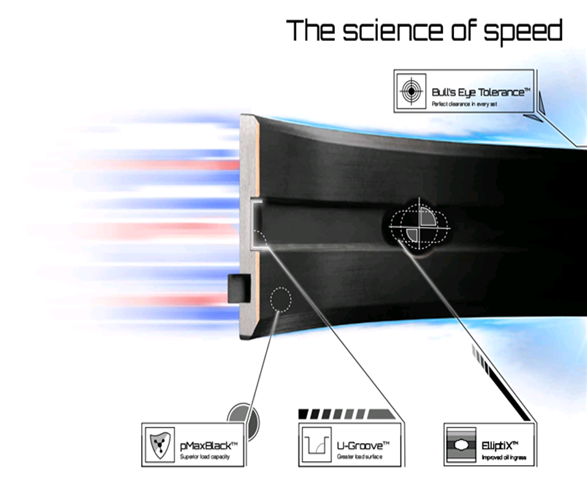

Bull’s Eye Tolerance™

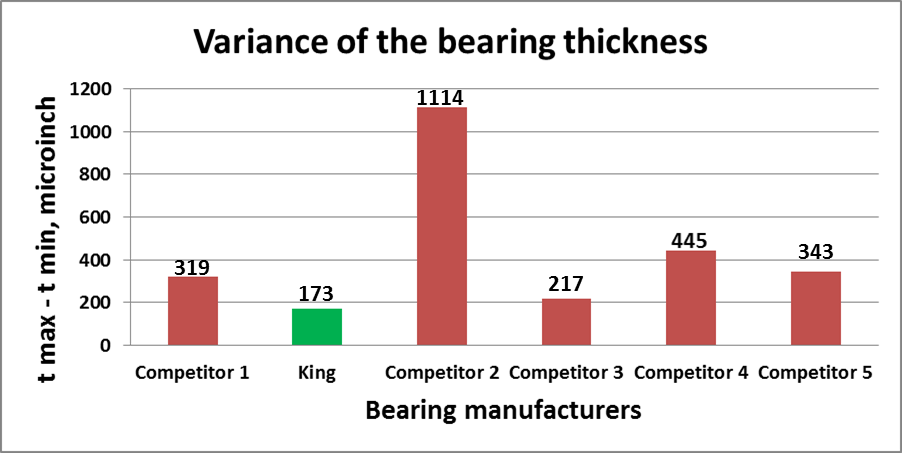

This study proves that oil clearance determines the |hydrodynamic parameters of lubrication. The bearing parameter that directly influences the value of oil clearance is wall thickness. Scattering the bearing wall thickness in a wide range causes inconsistent hydrodynamic parameters. Consistency of wall thickness produces more consistent hydrodynamic characteristics, and a more stable regime of hydrodynamic lubrication [3]. King Engine Bearings has developed and implemented a production technology ensuring the production of very accurate and consistent wall thickness from shell to shell. The technology is called Bull’s Eye Tolerance™. It includes fully automatic processes of precise boring and thickness measurement performed with machines developed and designed by King engineers. The process is integrated into the quality assurance system of the factory, monitoring the production process and the machines’ performance. The level of accuracy of Bull’s Eye as compared to that of other bearing manufacturers was evaluated by SGS S.A. – a multinational company headquartered in Geneva, Switzerland. SGS S.A. provides inspection, verification, testing and certification services. Identical bearings produced by 6 different leading bearing manufacturers were measured in the investigation. 32 bearings (4 sets with 8 pieces each) from each manufacturer were compared. The wall thickness of each bearing was measured in two points of the bearing crown (384 measurements total). The statistical variances of the measurement results [4] are shown graphically in Fig.10.

Fig.10 Statistical variances of bearing wall thickness

Among all evaluated products, King bearings exhibited the least statistical variance of 173 µinch. The variances of the bearing thickness of other manufacturers were between 217 to 1114 µinch. The values of the standard deviations of bearing wall thickness of each manufacturer are presented in Fig.11.

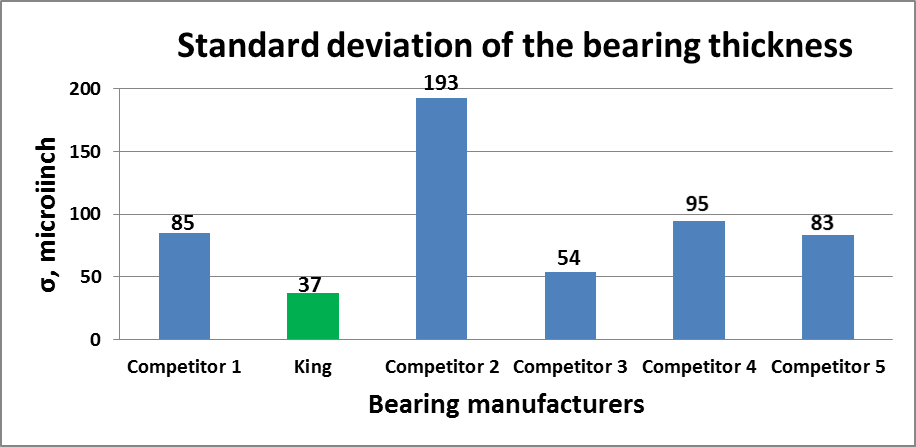

Fig.11 Standard deviations of bearing wall thickness measurements

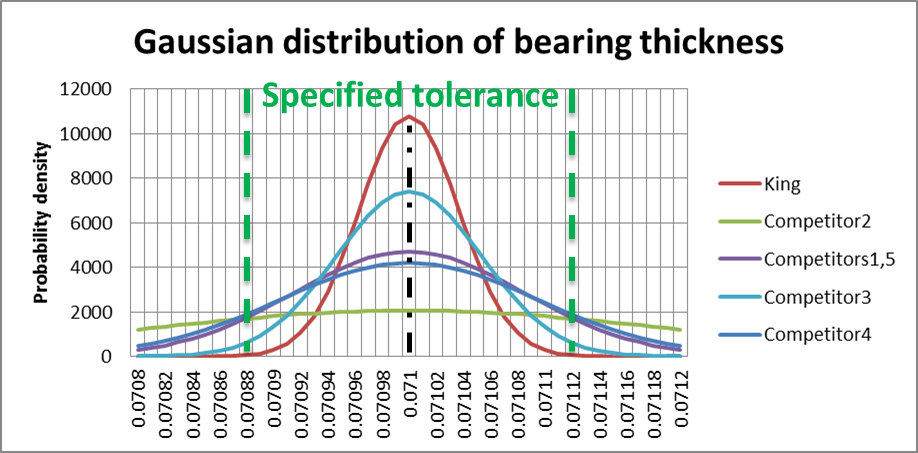

Standard deviation characterizes consistency of the measurement results. King bearings showed the best wall thickness consistency of all bearings tested in this investigation. The standard deviation of King bearing thickness is 37 µinch, whereas that of other manufacturers varied between 54 to 193 µinch. The values of standard deviations were used for building curves of Gaussian (normal) distribution of bearing thickness (Fig.12).

Fig.12 Gaussian distribution of wall thickness of bearings made by different manufacturers

Fig.12 depicts the clear advantage of King technology Bull’s Eye Tolerance™ over the competitors by providing consistent shell-to-shell bearing wall thickness.

to top

Conclusions

- There is a value of clearance at which minimum oil film thickness reaches the maximum value.

- Loose clearance results in lower temperature rise, but in greater oil leakage (risk of oil starvation), and in higher oil pressure peak (risk of material fatigue).

- Tight clearance results in less oil leakage and lower peak oil pressure, but in greater oil temperature rise and greater sensitivity to geometric distortions of the housing and crankshaft.

- The optimal range of clearance is 0.0015-0.003” (for a bearing with 2” diameter). Looser clearances are more suitable for highly loaded engines working at high rotation speeds and with thicker oils. Tighter clearances provide a better combination of hydrodynamic parameters in less loaded engines working at lower rotation speeds and using thinner oils.

- Higher oil viscosity produces greater minimum oil film thickness, more power loss due to friction and more uniform oil film pressure.

- King Engine Bearings developed a production technology - Bull’s Eye Tolerance™ - ensuring very accurate wall thicknesses.

- The consistent shell-to-shell thickness of King bearings results in a minor difference of oil flow rate and a more stable hydrodynamic lubrication.

References

- [1] Dudley D. Fuller (1958), A Survey of Journal Bearing Literature, Amer. Soc. of Lubricating Engineers.

- [2] Dmitri Kopeliovich (2011), Geometry and Dimensional Tolerances of Engine Bearings, Engine professional, AERA., p.70-76.

- [3] Dmitri Kopeliovich (2015), Optimization of Clearance Design for High Performance Engine Bearings, SubsTech (Substances&Technologies), Available from http://www.substech.com/dokuwiki/doku.php?id=optimization_of_clearance_design_for_high_p erformance_engine_bearings

- [4] Dmitri Kopeliovich (2015), Consistency in Bearing Wall Thickness, SubsTech (Substances&Technologies), Available from http://www.substech.com/dokuwiki/doku.php?id=consistency_in_bearing_wall_thickness

Related internal links

to Metals

to Engine bearings