SubsTech’s sister website Smooth Sliding provides independent engineering consulting services that help you to solve engine bearing related issues: failures, material selection, geometry design and optimization of hydrodynamic conditions.

Smooth Sliding is an engineering consulting company run by Dr. Dmitri Kopeliovich:

- VP R&D of King Engine Bearings.

- World leading expert (32 years of experience) in design, technology and materials for Engine bearings in applications such as automotive, renewable energy, aviation, racing and others.

- Founder and owner of SubsTech (Substances & Technologies) – a leading professional website on Materials Science and Engineering.

- Author of numerous scientific and engineering publications and patents.

- Founder and owner of Smooth Sliding.

For further information and for requesting consulting services please visit our sister website Smooth Sliding.

to Metals

to Engine bearings

Ecological Aspects Of Engine Bearings

Dr. Dmitri Kopeliovich

National governments of industrialized countries have become increasingly concerned with the environmental impact of polutants emitted by motor vehicle exhaust, and the hazardous compounds that have been used in some vehicle components. Vehicle exhaust emissions is seen as a growing problem in large cities the world over.

The global aspect of ecological problems has motivated many countries to cooperate and coordinate their efforts to reduce the amount of environmental pollution. Many have initiated ecological monitoring and implemented restrictions and requirements with the purpose of controling and reducing motor vehicle emissions.

This article will discuss numerous aspects of Engine bearing materials and design and how these are associated with the modern ecological requirements of engine performance.

Low Viscosity Oils

An engine bearing is a sleeve type sliding device supporting the crankshaft and enabling its rotational movement. Engine bearings generally work in hydrodynamic regimes of friction. This requires the presence of a continuous lubricant film separating the bearing and journal surfaces. Hydrodynamic lubrication is characterized by relatively low coefficients of friction. However, power losses caused by the friction force that is generated by the lubricant being squeezed between the journal and the bearing may reach significant values.

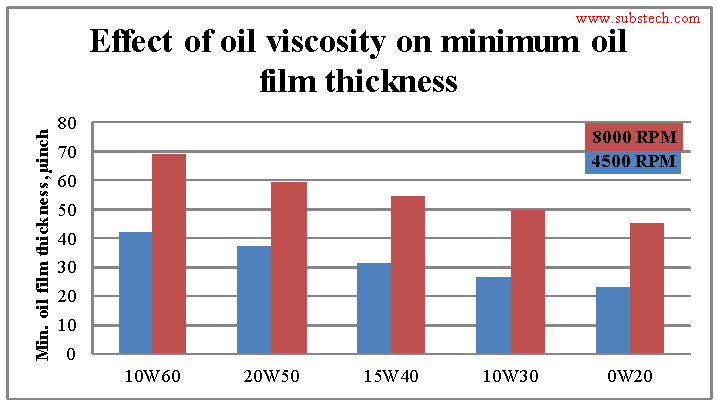

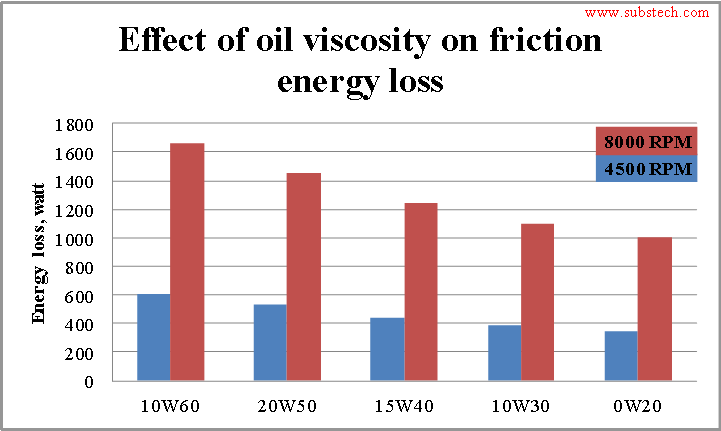

The factors affecting the value of the coefficient of hydrodynamic friction are: oil viscosity, rotation speed and oil clearance. Oils with a lower viscosity index produce lower friction. They improve engine efficiency (fuel economy) and reduce exhaust gas emissions. The effect of oil viscosity on power loss in a bearing is shown in the picture below. The results were obtained by King’s ENSIM calculation software.

Changing from 10w60 oil to low viscosity 0w20 results in a 40% reduction of power loss in the bearing. In addition to friction reduction, low viscosity oils cling less to the connecting rod surface, thus reducing effective rod weight. Since connecting rods perform accelerating (reciprocating) movement, the power required for the inertia forces is proportional to the rod weight. With less oil adhering to the rod surfaces, less power is required for their movement.

In spite of the clear advantages of low viscosity oils, they can not be used in all existing engines. Use of light weight oils requires a much lower bearing-to-journal oil clearance. The greater resistance (friction) of higher viscosity oils helps to generate a stable hydrodynamic force. It is this force that keeps apart the surfaces of the bearing and the journal at relatively large oil clearances. In order to obtain stable hydrodynamic lubrication with low viscosity oils, much lower oil clearances are required. The main parameter reflecting stability of hydrodynamic lubrication is minimum oil film thickness. The effect of oil viscosity on min. oil film thickness in a connecting rod bearing of a high performance highly loaded engine is shown in the graph (bearing diameter 2”, oil clearance 0.002”).

As seen in the graph, the value of min. oil film thickness may drop to critical levels at low rotation speeds - particularly in high load high performance engines.

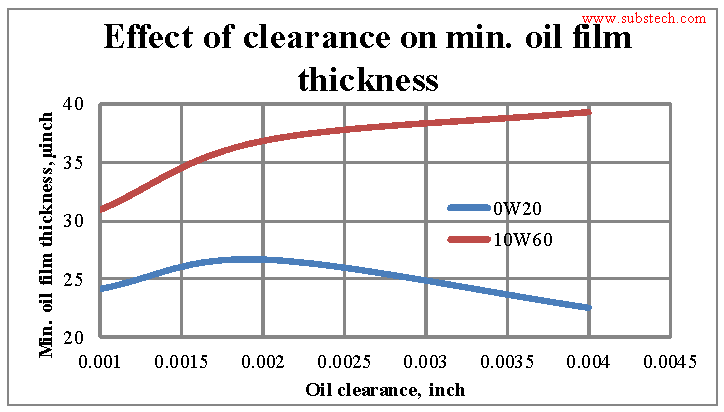

The effect of the value of oil clearance on minimum oil film thickness in a connecting rod bearing of a medium load passenger car engine is shown in the graph below.

A low viscosity oil is capable of maintaining stable hydrodynamic lubrication between the bearings and crank journals with relatively low oil clearance (below 0.0025”). However “thick” oil works better with clearances exceeding 0.0025”.

to top

ZDDP

ZDDP (Zinc dialkyldithiophosphate) is an anti-wearand anti-seizure additive that prevents direct metal-to-metal contact between the parts when the oil film is broken down. The use of anti-wear additives results in longer machine life due to higher wear resistance and better score resistance of the components.

The mechanism of anti-wear additives: the additive reacts with the component’s metal surface, forming a very thin solid film which may slide over the friction surface. ZDDP is the most effective in preventing seizure and reducing wear of cam lobes, buckets and followers, which experience metal-to-metal contact in their operation.

However, in modern highly loaded engines working with low viscosity oils (mineral and synthetic), the condition of intermittent metal-to-metal contact between the bearing and journal surfaces is common. Therefore a presence of ZDDP in the oil helps to prolong bearing life and reduce wear caused by micro-seizure between the rubbing surfaces.

The minimum content of ZDDP providing a sufficient level of anti-wear properties is equivalent to the concentration of zinc 1.2% (1200 ppm). Unfortunately, the use of ZDDP has a strong impact on the environment: ZDDP is toxic to humans and aquatic wildlife Zinc and phosphates clog catalytic converters, compromising their ability to reduce toxic pollutants in exhaust gas

For the last 40 years, governments have imposed environmental restrictions on the maximum level of ZDDP in motor oils. Modern passenger car engines are designed to operate with oils containing 0.8% (800 ppm) of zinc or even less (ZDDP content in oils for high performance engines is commonly not reduced). Lower valve spring pressures and the substitution of roller lifters for flat tappet lifters have reduced the pressure of the metal-to-metal contact in the valve mechanism.

Despite the fact that engine bearings are less sensitive than valve parts to the content of ZDDP, the combination of higher specific loads applied to the bearings, lower oil viscosity and lower ZDDP content results in frequent breaking of the hydrodynamic lubrication regime. Bearings in modern engines experience metal-to-metal contact much more frequently than in classic older engines.

In order to prevent seizure and reduce wear of a bearing material, it should have enhanced anti-friction properties. This may be achieved by incorporating Solid lubricants into the bearing material structure. King Engine Bearings has developed GP/SV bearings made of a strong intermediate copper alloy and a high strength metallic overlay containing dispersed particles of a solid lubricant. The GP/SV overlay has not only extremely high fatigue strength of up to 17,400 psi (~120 MPa), but is also wear and seizure resistant. The material is used in high load high performance and passenger car engines. An even more significant effect of enhancing anti-friction properties was obtained with bearings having an additional polymer coating containing a solid lubricant such as molybdenum disulfide, PTFE or graphite.

to top

Diesel Engines

Diesel engines have considerable advantages over gasoline engines with regard to environmental pollution. Diesel fuel produces 11% more energy than the same volume of gasoline fuel. Additionally, diesel engines operate at cylinder pressures twice that of gasoline engines. Therefore the efficiency of diesel engines is higher.

The total advantage of diesel engine fuel efficiency is about 40% greater than gasoline engines. Also, diesel’s lower fuel consumption results in lower exhaust gas emissions. The chemical composition of diesel gas emission is different from that of gasoline. Diesel exhaust gases contain much less CO (carbon monoxide), but more nitrogen oxides. The content of carbon dioxide (CO2, greenhouse gas) is lower in diesel emissions. The most pollutant laden emission is produced by cold engines. Advantage diesel engines because they warm up faster than gasoline engines.

Thus, diesel engines are a more ecological engine, and their popularity is increasing . In Europe, more than half of total passenger vehicle sales are diesel powered. In the USA gasoline powered cars are still more popular, but sales of diesel engine cars are growing every year.

The better fuel efficiency of diesel engines is due mostly to their higher compression ratio. It is about 20:1 in contrast to gasoline engines with about 10:1. Higher compression, together with a greater energy output and turbocharging, lead to much higher cylinder pressures – they can reach 200-230 atm. The load produced by the pressure is transmitted by the connecting rod to the upper part of the connecting rod bearing. In modern diesel engines the specific load applied to the rod bearing is about 15,000 psi (~100 MPa). Most Engine bearing materials have fatigue strength below 15,000 psi. Therefore they are not capable of withstanding such high loads.

Tri-metal sputter bearings with an overlay composed of an aluminum-tin alloy deposited by physical vapor deposition (PVD) were developed for high load diesel engines. As a cost effective alternative to the sputter bearing, King has developed tri-metal GP/SV material having a load capacity similar to that of sputter bearings.

to top

Start-stop and Hybrid Engines

In start-stop engines, idling time is reduced due to the automatic shut down of the engine when the car stops. The engine restarts when the brake is released or the clutch is depressed for selecting a gear. The start-stop system saves fuel when the car stops at a traffic light or is in a traffic jam. In urban traffic, fuel economy is increased by 5-10%. Since start-stop engines do not emit during the eliminated idling period, their total emission is reduced as compared to the classic engine. The start-stop system is also used in hybrid cars, combining the advantages of an internal combustion engine with an electric motor.

The ecological benefits of start-stop engines are evident. However, a start-stop system produces undesirable conditions for engine bearing operation . Engine bearings generally work in a hydrodynamic regime of lubrication, which is stable within a certain range of rotation speed. If the speed drops down, the hydrodynamic force decreases and becomes insufficient for counteracting the load applied to the bearings. Metal-to-metal contact ensues and the bearing material wears faster than in the hydrodynamic regime. Since start-stop engines shut down and restart very frequently (10 times more frequently than classic engines), the bearings operate in a condition of mixed lubrication (with metal-to-metal contact) much more of the time. Such conditions require bearing materials with greatly enhanced anti-friction properties.

The materials developed for start-stop engines contain an increased amount of solid lubricant. This compensates for the lack of liquid lubricant (oil) during mixed lubrication. Polymer coatings containing a relatively large amount of solid lubricant particles (molybdenum disulfide, graphite or PTFE) are being developed for start-stop/hybrid engine applications. The coatings may also contain particles of reinforcing phase added to the material for greater strength and wear resistance.

to top

Lead-free Materials

Lead is an excellent anti-friction material having an exclusive combination of properties:

Low coefficient of friction Low shear strength Excellent seizure resistance Excellent conformability Excellent embedability Technological conveniences: machinability, castability, easily electroplated Low cost

Due to its properties, lead has been widely used in Engine bearing materials: leaded bronzes, cast babbitts, Lead based engine bearing overlays. Relatively thick cast babbitts and overlays were very suitable for old engines characterized by low-to-medium loads, contaminated oils and geometric irregularities.

Leaded materials are still very popular in modern high performance engines. This is because their bearings work much more time in a mixed regime of lubrication. Under these conditions there is metal-to-metal contact, and the soft surface properties of lead are critical. The chief disadvantage of conventional lead based overlays is low load capacity. King Engine Bearings has developed an effective method of surface hardening lead based overlays. The new pMax Black™ leaded overlay has proven its effectiveness in increasing the fatigue strength of high performance tri-metal bearings.

Today the use of lead is under strict governmental regulations and rules. Lead is a toxic heavy metal affecting human heart, bones, kidneys, reproductive and nervous systems. In most countries (including the U.S.A.), automobile manufacturers are no longer allowed to use bearing materials containing lead. Bearings manufactured for the OE market must be lead-free.

Environmental restrictions and regulations motivate engine bearing manufacturers to develop new effective materials which do not contain lead. One of the most promising candidates for replacing lead is bismuth. It has similar anti-friction properties to lead, but is considered environmentally friendly. Bismuth is used as an anti-friction additive in copper alloys. Bismuth may also be used in the form of overlays.

Another metallic material which may replace lead in the overlays of tri-metal bearings is tin. Tin is already utilized in bi-metal lead-free bearing constructions in the form of the aluminum-tin lining. These bearings are used for many moderate load applications.

Excellent anti-friction properties, even better than those of lead, may be achieved by applying polymer coatings containing effective Solid lubricants (such as molybdenum disulfide, graphite or PTFE).

In applications requiring high load capacity, lead-free tri-metal materials such as King proprietary GP/SV bearings or sputter bearings are used. King Engine Bearings has developed a wide range of effective lead-free materials for different types of engines.

In parallel, King has upgraded the performance of traditional leaded materials and manufactures leaded bearings for applications where such materials are required: high performance and aviation engines.

to top

Conclusions

Modern ecological requirements and restrictions demand modifications of engine bearing design, and the development of new bearing materials. Tighter oil clearances are required for the stable hydrodynamic lubrication of bearings working with low viscosity oil . Bearing materials with enhanced anti-friction properties should be used when combined with oils having reduced ZDDP content . Increased popularity of the more efficient and environmentally friendly diesel engine is producing a growing demand for bearing materials whose load capacity exceeds 15,000 psi (100 MPa). Bearing materials containing a large amount of Solid lubricants are required for start-stop and hybrid engines. Leaded bearing materials may be replaced with new effective lead-free materials containing bismuth, tin or solid lubricants.

to top

Related internal links

to Metals

to Engine bearings